Item shown may not be actual product.

Item shown may not be actual product.Product and price information are subject to change without notice.

Discontinued

Auto 34 Tire Changer

Description

The Hunter Auto34’s exclusive features operate in harmony to easily and safely change the world’s toughest new performance tires and wheels. Its intuitive controls allow for unmatched cycle times and a short learning curve. The leverless operation eliminates technicians straining to pull over tough beads, damage of beads with thick levers, and rim damage from lever during demounting.

Features

-

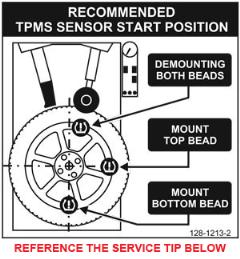

Leverless Tool Head – The ultra-thin, vertical shape of the tool head automatically slips easily between the rim and tire sidewall and extracts the bead gently in one fluid down and up motion without the use of bead levers. The slim head design and elimination of levers reduce tension on the bead and ease overall operation.

-

Diameter Control – The single diameter control arm adjusts the tool head and rollers to the correct diameter. No other adjustment is needed.

-

Simple Controls – Three switches and one foot pedal control virtually all the tire changing operations.

-

Simple Clamping – The center support clamping table and self-centering quick clamp provide the flexibility to easily mount a variety of wheel designs up to 34” in diameter. With three easily adjustable clamping heights, no flange plates are needed for most reverse wheels. The rubber cover protects expensive wheels from damage.

-

Blast Inflation – Handheld nozzle allows operator to direct a large burst of compressed air exactly where needed to easily seat the bead. A compression trigger and foot pedal protect the operator from accidental discharge.

-

Bead Loosening Roller Auto Indention – The roller system gently rolls the tire off or on the rim, yet is strong enough to hold the tire securely for safe match-mounting. A sensor on the bead loosening roller detects when the roller is under the rim flange and automatically indents. When backing out, the roller moves away from the rim then out, to eliminate rim contact.

-

Bead Press Arm – The standard bead press arm assists in mounting difficult tires. The bead press arm is secured to the tool head controls and is cleared out of the way automatically as the tool head is raised.

-

Wheel Support Plate – Center clamps for maximum diameter flexibility. Adjustable to three working heights. Innovative Expandable Base – The three-position base provides the versatility to service wheels in ranges of 10” - 30”, 12” - 32”, and 14” - 34”. No expensive kits or modifications are required.

-

Wheel Lift – Eases the service of large wheel assemblies, reduces operator fatigue and allows for more careful handling of expensive reverse wheels. (Available separately as an optional add-on to the HUNTCA34.)

Includes

- HUNRP6G10A80 RP6-G1000A80 Quick clamp center shaft with 90° lock

- HUNRP6G10A67 RP6-G1000A67 Traction bar with extension and 28" bead depressor tail

- HUNRP6713421 RP6-710013421 (2) wheel support plate guards for reverse wheels

- HUNRP61157 Truck Cone

- HUNRP6-3784 Mounting Paste, 3.5 kg

- HUNRP6-1506 Applicator Brush

Accessories

- HUNRP6G10A89 RP6-G1000A89 Insert Ready Tool Head

- HUN2022361 Wheel Lift

- HUNRP6G10A86 RP6-G1000A86 Mirror

- HUNRP6G10A73 RP6G1000A73 Pax Kit

Warranty

Hunter Engineering Company warrants new equipment to be free from defects in material and workmanship under normal conditions of use for a period of one year (1) from the date of installation. Items warranted for a period of three years include, but are not limited to, all circuit boards, PCs (1)(2) and options installed inside the PC, CRTs (except 111 aligners), power supplies, transducers (3), and wheel balancer motors.

(1) During the first 30 days, complete PCs will be replaced at no charge under warranty. After 30 days, they will be repaired at no charge under warranty. All internal PC components will be replaced at no charge for a period of three years from the date of installation. During the first 90 days, the TC inflator box will be replaced at no charge under warranty; parts will replaced as needed for one year. (2) Printers may be exchanged during the first 90 days under warranty, then they may be repaired under warranty for an additional period of nine months. (3) Transducers include camber cells, brake tester load and weight cells, suspension analyzer pickups, and balancer force transducers.

Product Specifications

- Clamping System Rotating Speed: CW - Variable up to 15 r.p.m. CCW - 7 r.p.m.

- Maximum Bead Roller Opening Width: 19"

- Electrical: 208-230 volt, 1 phase, 15 amps NEMA L6-20P Plug

- Approximate Shipping Weight: 816 lbs.

- Maximum Space Dimensions: 68"L x 43"W x 72"H

- Bead Roller Power - Each Roller: 4,170 lbs. @ 140 p.s.i.

- Torque: 867 ft.-lbs.

- Recommended Air Supply: 115-175 p.s.i.

- Maximum Tire Diameter: 50" / 52" / 54"

- Max. Bead Loosening Power; Each Arm: 2,645 lbs. @ 140 p.s.i.

- Max. Bead Loosening Opening Width: 15"

- Bead Roller Diameter Range: 10"-30" / 12"-32" / 14"-34"